Simplify Safety to Save Time, Money, and Lives

The hidden tax of complexity

Across North America, safety leaders are managing more risk with fewer people and tighter budgets. Simplified safety management for lone workers is becoming increasingly necessary in this challenging environment. Many safety leaders feel that streamlined lone-worker safety management programs are a bit of a pipe dream. When the safety program turns into a patchwork—one system for check-ins, another for reporting, another for monitoring and call-outs—every new login, manual step, and “who’s on call?” moment adds friction. That friction is expensive. In 2023, the total cost of work injuries reached $176.5 billion, including $59.5 billion in administrative expenses such as coordination, paperwork, and claims handling—the burn nobody budgets for but everyone feels. Injury Facts

Simplified, streamline safety management for lone workers is the light at the end of the tunnel of complexity and slows response. Lone-worker incidents escalate quickly; minutes matter. If your process requires a person to remember a check-in, a supervisor to notice the miss, and another team to trigger escalation, you’ve designed in multiple delays. Modern monitoring tech such as Be Safe, exist to remove those delays with real-time alerts, two-way communication, and documented escalation pathways that make action the default, not the exception. National Safety Council

Working alone raises the stakes—so the process must be simple

Lone workers face the same hazards as others, but being alone can increase the likelihood and severity of outcomes—and they’re not a niche group. NSC’s Work to Zero cites an estimated 53 million lone workers across the U.S., Canada, and Europe, with roughly 15% of the overall workforce operating alone in some capacity. That includes oil & gas technicians, environmental services crews, utility workers, and remote maintenance teams. National Safety Council

Regulators are clear about what good looks like: robust training, supervision, and keeping in touch with team members. This essential foundation provides crucial capability to respond quickly following an incident on a site or in the field. The UK’s HSE says employers must “keep in touch with [lone workers] and respond to any incident.” In British Columbia, employers must have a written check-in procedure that defines intervals and what to do when contact is lost, including emergency rescue provisions. Federally in Canada, the Labour Program ties working-alone safeguards to the hazard prevention program—identify the risks, put controls in place, and make communication predictable. None of that is easy with a manual, ad-hoc process. WorkSafeBC Government of Canada

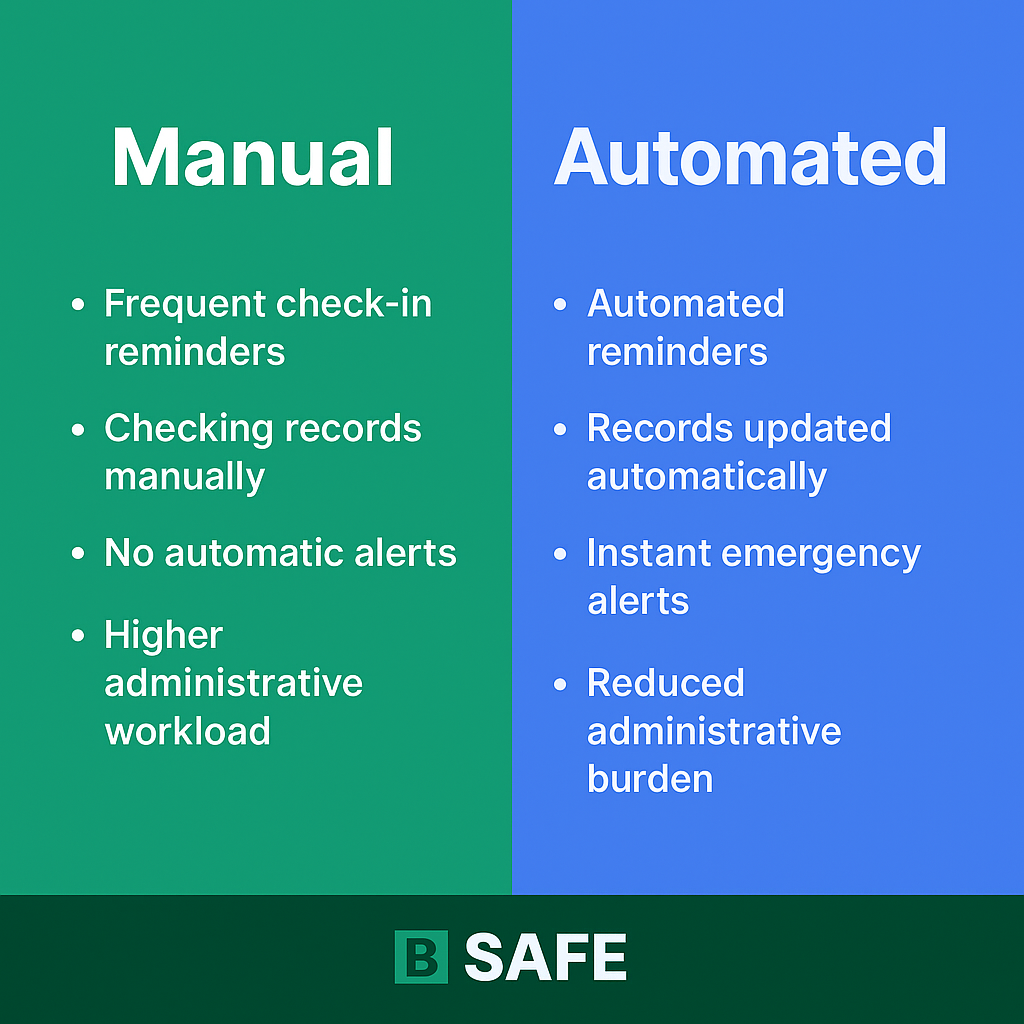

Why manual or internally managed check-ins underperform

Manual check-ins look simple on paper: send a text at the top of the hour; call if there’s no reply. In practice, they produce gaps—missed pings, stale contact trees, late escalations, and poor records. NSC’s Work to Zero white paper on lone-worker monitoring spells out the fix: automated scheduling, two-way channels, and device/app triggers (e.g., fall/no-motion) that raise the alarm even when a worker cannot. That same research notes common adoption barriers, including privacy questions and the perception of implementation effort—precisely the barriers a streamlined, vendor-supported rollout is designed to overcome. National Safety Council

Ultimately, there’s also the audit problem. When records live in emails and spreadsheets, compiling proof of due diligence can take days to compile. Automated systems create time-stamped logs for check-ins, alerts, responses, and outcomes. These reports are evidence you can hand to leadership, regulators, or investigators without a scavenger hunt. National Safety Council

Two vendors, one job: why fragmentation adds risk and cost

Splitting software and 24/7 human monitoring between different providers often means split accountability and slower coordination during an event—the opposite of what you want when a lone worker needs help now. It also doubles administrative burdens, training, and creates data silos that complicate incident reviews. While the research on tool-sprawl typically comes from IT and operations, the lesson maps cleanly to safety: consolidation reduces friction and makes it easier to keep procedures simple, consistent, and testable. (Reasoned inference; operational principle consistent with consolidation research.)

The ROI of simplification – Simplified safety management for lone workers

The business case is no longer theoretical. NSC’s 2023–2024 materials tie technology adoption to faster response, better outcomes for isolated workers, and lower administrative burden—exactly what happens when automated check-ins and escalation are built into the workflow rather than bolted on. Meanwhile, the macro cost picture (the $176.5 billion above) reminds leaders where the money really goes: lost time and administration, not just medical bills. Simplifying the safety stack is one of the few moves that both improves protection and shrinks the paperwork footprint. National Safety Council Injury Facts

Higher-risk work in sectors such as oil & gas, utilities, and remote field services still record thousands of fatal work injuries each year, underscoring the need for swift, reliable escalation when workers are alone or out of sight. Bureau of Labor Statistics

What “simple” looks like (and why leaders and remote workers prefer it)

A simplified lone-worker program defaults to safety. Workers don’t need to memorize steps, and administrators don’t need to make every update two or three times, between systems. Supervisors don’t need to babysit check-ins. Leaders don’t need to chase evidence. In practice, that looks like:

- Automated check-ins and event triggers (missed check-in/missed shift/SOS) that are impossible to “forget.”

- Two-way communication: voice and messaging; so the right people are alerted and respond quickly.

- Centralized, time-stamped records for audits, investigations, compliance, and program adoption reviews.

- One solution accountable for software, 24/7 human monitoring, implementation, and support, so training is minimal and onboarding is fast. National Safety Council

For business and safety leaders, the appeal isn’t just fewer tools—it’s fewer steps, fewer meetings, fewer unknowns, and a cleaner line of sight to “Are our people OK?” and “Can we prove it?”

Addressing the usual objections—head-on

“We don’t have the capacity to roll out something new.”

That’s exactly the point of simplified lone worker safety. Choose a partner that handles setup, training, and support so your team isn’t lifting. NSC’s research shows adoption improves when employees are involved early, benefits are explained plainly, and the process is transparent—steps a capable provider will lead for you. National Safety Council

“Manual check-ins worked fine for years.”

They work—right up until they don’t. Lost signals, missed texts, and unclear escalation add time and risk. Regulators expect defined intervals, documented procedures, and prompt response; automation helps you deliver that consistently. WorkSafeBCHSE

“Our field connectivity is spotty.”

That’s where layered communication methods (scheduled check-ins + device triggers + resilient channels) shine. The objective is predictable communication with proof, not perfect coverage. Design the workflow to fail-safe: if a check-in doesn’t arrive, escalation triggers anyway. National Safety Council

Practical compliance, without the chaos

- Canada (federal): Working-alone safeguards are part of the Hazard Prevention Program; assess hazards, implement controls, and formalize communication and check-ins. Government of Canada

- B.C.: Employers must implement a written check-in procedure, including timing and rescue steps. WorkSafeBC

- UK: Employers must keep in touch with lone workers and respond to incidents. HSE

Simplified safety management program for lone workers involves a semi-automated platform with two-way communication and built-in logging, aligning cleanly with these expectations, turning compliance from a scramble into a by-product of normal work. National Safety Council

If you’re budgeting now, make this the year you buy down risk

Reducing spend and increasing program performance are not mutually exclusive. Streamlining and unifying your lone-worker safety program cuts administrative overhead, shrinks time-to-escalation, and strengthens audit-readiness. A simple and unified lone worker program creates a calmer, more confident experience for supervisors and crews. In short: safety gets easier to do right, every day. Injury Facts National Safety Council

Be Safe was built for that outcome: an all-inclusive model (software + 24/7 human monitoring + setup + training + support), designed to require almost no training for frontline users, with implementation led by us so your team doesn’t carry the admin load. The goal is simple: fewer steps, fewer vendors, faster help, better proof—and safer people, every shift.

FAQ

What’s the business case for simplifying lone-worker programs?

The $176.5 billion injury-cost figure in 2023 includes a large administrative component; automation and consolidation reduce that burden while improving response and compliance. Injury Facts

Do regulators allow automated check-ins?

Yes. Guidance emphasizes reliable communication, documented intervals, and clear escalation—all of which automated systems provide when configured correctly. WorkSafeBCHSE

What are the must-have features for lone-worker tech?

NSC highlights two-way communication, real-time alerts, GPS/location, and audit-ready logging as core capabilities. National Safety Council

Check out other articles by Be Safe: